|

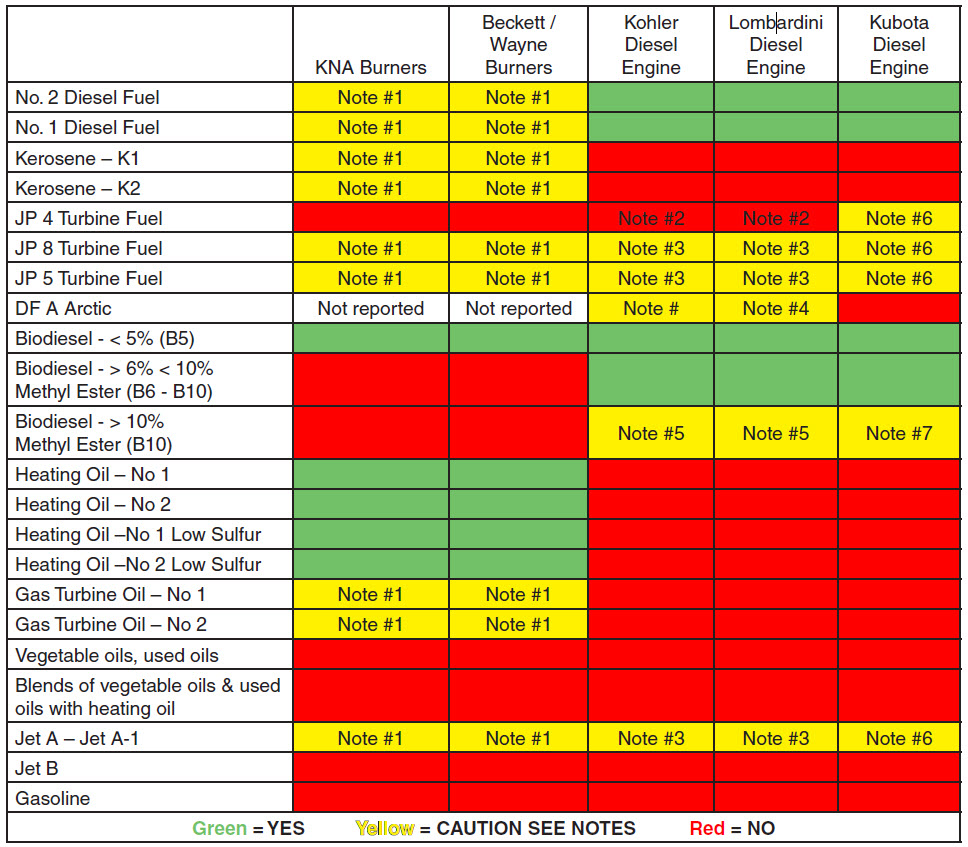

Note #1 = These are not fully listed with UL. However, they have been used successfully and in some cases, may be used to address certain fuel or combustion issues.

Note #2 = JP 4 Not recommended. Should be used only in emergency situations. JP 4 severely reduces engine life and potential power due to the lack of lubricity as compared to DF2.

Note #3 = 5-12 % reduction in power and up to a 30% reduction in fuel system component and upper cylinder life.

Note #4 = Acceptable fuel for use in areas with sub-zero ambient temperatures only.

Note #5 = Up to 5% reduction in power. Lube oil change and fuel filter change intervals must be shortened. Periodic check of hoses and seals should be conducted. Engine can operate only on biodiesel blends up to 20% methyl ester (B20). Biodiesel blends must be purchased from a BQ-9000 Certified Marketer and meet the American Society for Testing & Materials (ASTM) specifications for biodiesel under ASTM D6751 for North America. In Europe, biodiesel blends must meet the EN14214 standard. DF1 and DF2 used in biodiesel blends must meet the specifications of ASTM D975. Biodiesel has a strong cleansing effect. Initial use will typically result in a collection of deposits from fuel lines and the fuel tank from previous use of diesel at the fuel filter. Therefore the fuel filter must be changed 30-50 hours after changing over from diesel to biodiesel. Fuel dilution of lube oil is possible with the use of biodiesel. Therefore, halved lube oil change intervals must be introduced. Periodic checks of hoses and seals must be conducted. Biodiesel has a high cloud point so heating the fuel is necessary for low ambient temperature operation to avoid waxing or gelling. Engine storage with biodiesel longer than 4-6 weeks must be avoided. Prior to storing an engine, it is recommended to operate the engine with DF2 or DF1 (whichever is appropriate for the ambient conditions). Based on the above table, it should be noted that the operation of the diesel engine on fuels other than DF2/DF1 will require the use of a revised maintenance schedule, including, but not limited to, oil change interval, injectors/injection system, and cylinder head components. Also of note, the amount and severity of engine/component and power degradation will depend upon load and operation conditions to which the engine is subjected. Due to the fact that diesel engines are commercial/industrial engines and thus designed to operate utilizing commercial diesel fuel (DF2/DF1), engine/component failures that can be directly attributed to the use of poor quality fuels or contaminated fuels cannot be covered under the standard commercial warranty.

Note #6 = Aviation fuels suitable for use in this engine include JP5, JP4, JP8 and, JET-A (if 5 percent oil is added).

Note #7 = Fuels containing less than 20% methyl ester or B20, are suitable for use in this. Biodiesel fuels meeting the specification of BQ-9000, EN14214 or equivalent are recommended. DO NOT use vegetable oil as a biofuel for this engine. Any failures resulting from the use of fuels other than recommended will not be warranted.

Note #8 = Karcher advises on their classic burners only refill diesel oil or light fuel oil.

|

.jpg)