|

|

|

Pressure Washers & Steam Cleaners Parts Washers Water Treatment Systems Vapor Steam Cleaning Equipment Floor Care Equipment Industrial Vacuums Ice Blasters Steam Generators & Hot Water Heaters Detergents & Chemicals Custom Design Equipment Accessories / Misc. Equipment Rebuilt Equipment |

Lorchem Learning Center | Principles of Filtration | Cyclonic Filtration This 3-part educational article will cover the three main types of filtration commonly used in today’s industrial vacuum cleaners: cyclonic, mechanical and chemical filtration. Every vacuum cleaner ever sold has incorporated at least one of these types of filtration. Some of the earliest vacuum cleaners only used cyclonic filtration while other, more complicated modern machines, use all three. Read more about each of these filtration systems in this 3-part article:

Before purchasing a vacuum cleaner, the buyer should have at least a basic understanding of the filtration system inside the machine. No matter how powerful, expensive or “feature rich” a vacuum cleaner may appear to be, a vacuum is only as good as the design of it’s filtration system. The main function of vacuum’s filtration system is to remove particulate (or vapors) from the airstream that could be harmful to the user of the vacuum or to the vacuum’s motor. Filters are often designed to capture a wide variety of different sized particles and different types of materials. Filters also need to last for a reasonable amount of time; they must be easy to replace and should not be overly expensive. Many different factors are considered during the design process of a high quality vacuum cleaner. None of them however, are more important than filtration. Go back to the Lorchem Learning Center. PART I: CYCLONIC FILTRATIONArticle courtesy of Nilfisk Industrial Vacuums Cyclonic filtration is probably the easiest of the three types of filtration to understand. This is probably why it was the type of filtration used in the first commercially produced vacuum cleaners around the turn of the century. An Englishman named H. C. Booth is credited as the inventor of the first electrically powered vacuum cleaner in 1901. Booth’s first vacuum was extremely simple and did not use any type of filtration system. His vacuum simply demonstrated how dirt could be picked up more effectively using the principle of suction instead of forced or blown air.

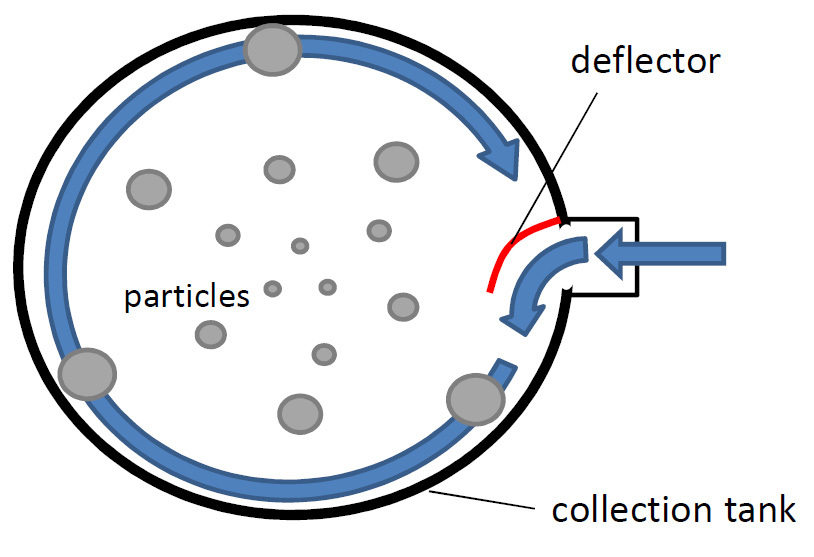

In simple terms, cyclonic filtration is really nothing more than the clever use of physics. Fisker learned that by channeling air into the form of a cyclone, dirt and dust could literally be “spun” out of the airstream by centrifugal force. Using a simple deflector, the air entering into the vacuum’s collection tank is directed into a spiral shape. Centrifugal force causes the larger, more dense particles to move towards the outer edge of the spiral (as shown below) where the air moves more slowly. The forces of gravity cause larger particles to drop out of the airstream and into the collection tank. Lighter particles that reach the outer edge of the spiral against the tank wall will slow down due to friction and will eventually fall down into the tank. Cyclonic filtration can not be expected to remove all of the particles in the airstream. Some particles will be too small or lightweight and will remain trapped in the airstream. If harmless, these particles can often pass directly through the vacuum’s motor. Otherwise, they will need to be captured by a mechanical filter. Examples of Cyclonic Filters

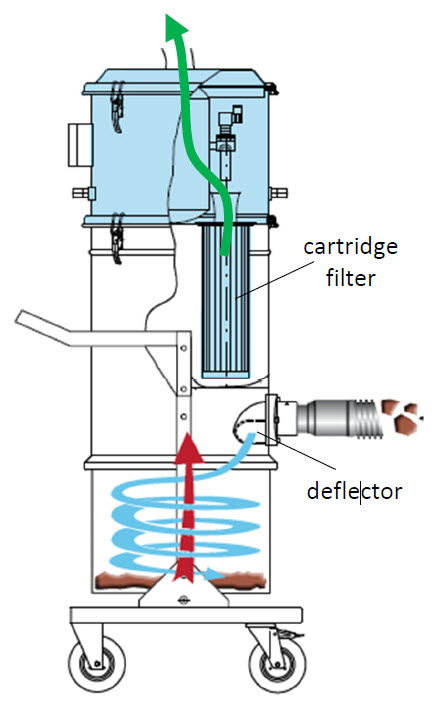

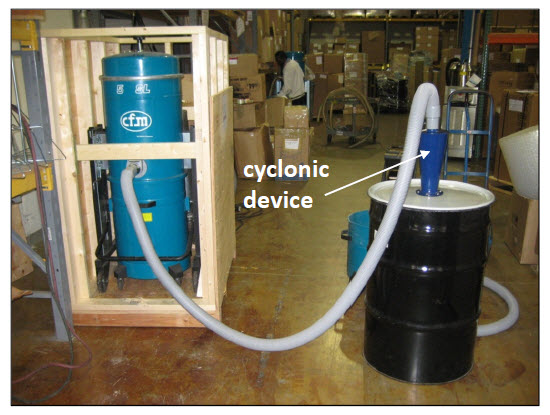

C Industrial vacuum manufacturers have used cyclonic filtration for many years. The image to the right shows how a deflector is used as the first “stage” of filtration in a multistage dust collector. Large particles are spun out of the airstream in the tank (blue arrow) while smaller particles continue upward (red arrow) to a second stage of filtration. Here large cartridge filters are mounted to capture the smaller, finer particles. Any particles small enough to pass through the cartridge filters pass out of the dust collector (green arrow) possibly to another filter or simply out to the surrounding environment. The deflector is simple, has no moving parts, rarely ever wears out and is easy to incorporate into almost any type of filtration container. These are some of the reasons why they are so popular. The Cyclonic PreseparatorI In this experiment, samples of flour and concrete dust were collected from the floor into the preseparator test how effective the device would be at capturing very fine dust. Any material that passed directly through the preseparator would collect in the tank and filters of the vacuum unit. This preseparator proved to be very effective as the photos demonstrate.

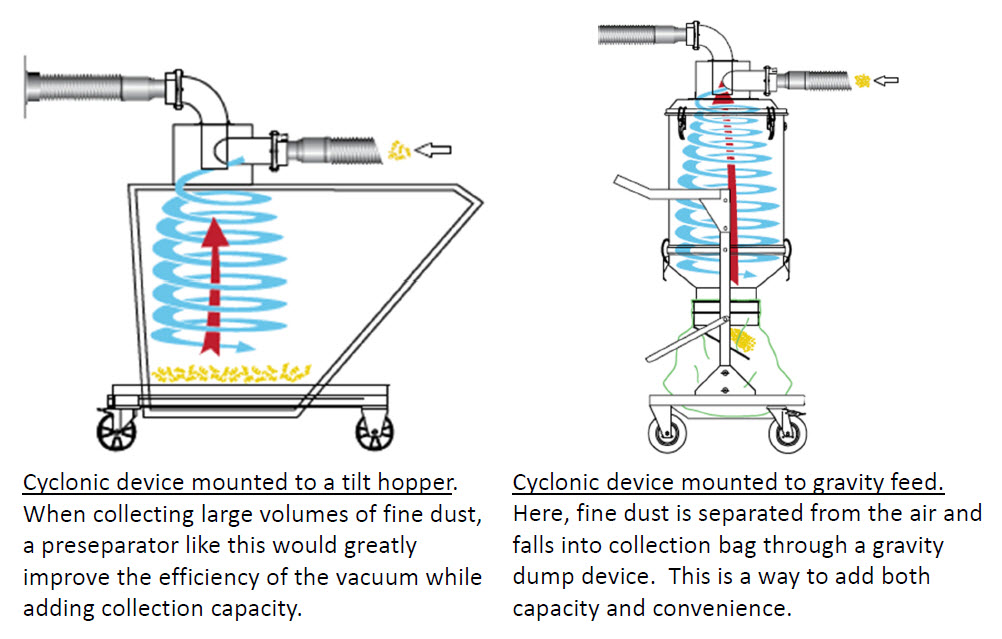

More Examples of Cyclonic Preseparators

|

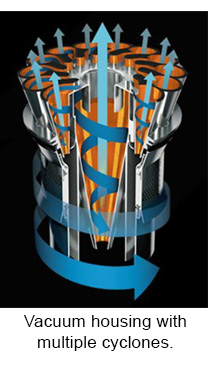

Recent advances in cyclonic filtration have had a major impact on the way many consumer (household) vacuum cleaners are designed today. Plastic housings can now be molded into much more complicated shapes where multiple cyclones can be used together to increase the overall effectiveness and efficiency of the cyclonic action.

Recent advances in cyclonic filtration have had a major impact on the way many consumer (household) vacuum cleaners are designed today. Plastic housings can now be molded into much more complicated shapes where multiple cyclones can be used together to increase the overall effectiveness and efficiency of the cyclonic action.

.jpg)

.jpg)